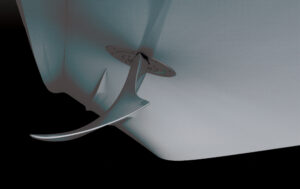

Prop Frosting

There are several methods for coating a propeller with anti-foulant.

Which one works best?

Over the years I’ve owned many a trusty watercraft, each with its own kind of running gear. My first, which I simply called “The Boat” and built myself, had a Sea King outboard that was so small I could carry it home, a feature that, when coupled with the fact that I did all my boating in fresh water at the time, kept me blissfully ignorant of barnacles. The vessel I own now—a 32-foot Grand Banks trawler named Betty Jane—is another story, however. In addition to her 24-inch propeller, she also has a metal grounding shoe and several exterior metal sea strainers, all of which need protection from the vagaries of salty seafestation.

Check out some prop-coating photos

About 50 years have elapsed between The Boat and Betty. And one way or another, during all that time, saltwater’s played a steadily increasing role in my life, thereby ensuring that anti-fouling coatings have played a steadily increasing role as well. I am not going to claim here that I’ve tried every conceivable propeller-protecting potion, spray, chemical wash, or DIY treatment out there, but hey…I’ve tried a few:

Interlux Trilux 33

This product manifested a few decades after I’d transitioned from British Seagull-energized sailing vessels to powerboats with outboards that refused to tilt their lower units wholly out of the water. Given the lack of capital that always plagues my boating endeavors, I was looking for a reasonably priced solution to my fouling issues one day when I came across a spraycan of Trilux 33 from Interlux (www.yachtpaint.com) in a marine store. The stuff, the can said, was expressly made to treat aluminum outboards. It was safe—no galvanic issues. Application? I simply cleaned the area I wanted to treat with soap and water, let it dry, and then broke out the sandpaper. Then finally I hit the area with some Interlux Primocon, a primer that promotes bonding between paint and metal, and followed up with the whole can of Trilux 33. Worked great! Today, spraycan versions of both Trilux and Primocon sell for $34 and $30 respectively.

Plain Ol’ Bottom Paint

As I evolved into inboards, I naively decided at one point to simply pressure wash my boat’s propellers, remove all the crud, and then merely recoat them with plain ol’ bottom paint. After all, there was usually some of the stuff left over after a bottom job. It was sorta free! At least in a sense. And why bother with expensive sandblasting anyway? Or slathering on a layer of resin that would keep the paint from reacting galvanically with the metal in the prop? The denouement? When my boat was finally launched, most of the paint went poof! during the first hour of running time! Never one to surrender though, I tried more plain ol’ bottom paint the next year and got the same deplorable result, even after going over the props with emery paper and a stout heart. Poof!

Pettit Prop Coat Barnacle Barrier

Back about 2010, I decided to try a little Prop Coat Barnacle Barrier from Pettit (www.pettitpaint.com) on Betty’s propeller. The yard had just finished up some work when I made this decision, Betty was still on the hard, and her big, squeaky-clean propeller glistened invitingly from the shade beneath her transom. Moreover, Prop Coat seemed attractively priced at $34.99 a can and, of course, I was well versed in aerosols by this time. I applied three separate layers to Betty’s prop, as well as her grounding shoe, allowing for some dry time between layers. My efforts produced a light-gray surface that looked good. But ultimately, I got only modest performance. According to the diver who addresses Betty’s nether areas on a monthly basis, my Prop Coat lasted about six months. Had I added a couple of layers of Hydrocoat Eco bottom paint, per Pettit’s Prop Coat data sheet, things might have gone more swimmingly.

Propspeed and Mussel Buster

The most recent and high-profile arrivals on the prop-coatings scene each have complicated application regimes. The first is PropSpeed (www.propspeedusa.com), an expensive offering that is sold in kit form. West Marine (www.westmarine.com) sells a quart-sized kit for about $470, with PropPrep/Cleaner adding an extra $120 or $210, depending on the amount purchased. Key to success with PropSpeed is meticulous cleaning of the metal involved. Another factor is time—application of the yellow etching primer must be followed up with the Clear Coat within just a few minutes. Due to all the hurry, at least two persons typically apply PropSpeed, one brushing primer and the other Clear Coat. There’s one more point worth mentioning—PropSpeed repairs no longer require a total recoating like they used to. Minor damage can now be fixed by simply sanding the affected area, cleaning it, and then applying more PropSpeed while making sure the new material abuts but does not overlap the old. The second coating that’s enjoying big-time popularity today is Mussel Buster (www.musselbuster.com), a product that requires a prop be removed and conveyed to Mussel Buster where an antifouling finish is literally baked on. The finish, enthusiasts say, may last for years. The hang-up? Serious damage must be addressed via an entirely new application. And the stuff’s pricey too. Treating a prop the size of Betty’s would run about $300 plus shipping and labor.

Nada?

Time for a confession. After Betty’s most recent haulout, I followed up with a prop treatment I’ve never attempted before—I did nothing at all. Zilch! “About 80 percent of our customers don’t put anything on their props these days either,” said Tom Owen, service manager of Sadler Point Marina in Jacksonville, Florida, Betty’s home away from home. “I guess that’s because it’s just so hard to get any kind of coating to stick to a propeller.”

Yeah, the gross negligence of it all bothers me occasionally, even causes some sleepless hours, I suppose. But hey, the guy who addresses Betty’s nether areas on a monthly basis tells me things are looking pretty darn good down there, prop included. Who da thunk?

How to Tweak Your Props to Make Your Boat More Efficient ▶