Bertram 35

Part of the Bertram 35’s charm is that while she is cruise-worthy, she is also eminently fishable. Check out the overhead rod stowage shown here in the salon of the boat. Just one of her standard-issue fish-fighting features.

Bertram 35

Foam-cored, teak-veneered panels make up much of the Bertram 35’s interior walls, bulkheads, and furnishings. Notice that the lockers under the dinette area in the salon shown here are thoroughly finished inside. A nice, residential touch.

Bertram 35

Yes, the faucet handles in the galley area of the Bertram 35’s salon are a little quirky. For some reason, they put us in mind of the fittings you’d encounter on a red fire hydrant. Distinctive, robust, maybe even a little bit cool? For sure.

Bertram 35

While our Bertram 35 test boat did not have an anchor windlass, you can have an optional Maxwell windlass installed (along with bow pulpit and anchor chocks) for $10,500.

Bertram 35

Okay, you’re looking at some extras here. The teak cockpit sole, teak combings, and teak covering boards on our Bertram 35 test boat were all optional. The cool upholstery on the engine-box cushions (which you can partially see) and the two fishboxes (each with its own macerator) are standard, however.

Bertram 35

Check out the so-called “jewel piece” at the stemhead of the Bertram 35. Yes, it’s a fairlead for the boat’s anchor rode when deployed, but it’s also an example of fine, artistically-executed, custom craftsmanship.

Bertram 35

A Bertram 35 in the making. The foam-filled “structural grid” is visible in part here. Notice the extra foam overlying the grid in the bow area. Its job is to reduce noise and vibration when, among other things, the boat is charging headseas.

Bertram 35

A few of the Bertram 35’s propulsion-related details include fairly large, plate-type, high-performance rudders (activated via SeaStar Optimus hydraulic steering), propeller tunnels, and heavy-duty bronze trim tabs.

The plumb bob shown here? Part of an upcoming drive-train alignment.

Bertram 35

How much extra speed will a hydro-dynamically-shaped strut barrel get you? We’re not sure. But we are sure we got an average top speed of 36.1 knots out of our Bertram 35 on test day. Who’s to say that streamlined strut barrels didn’t contribute at least a little to this rousing velocity.

Bertram 35

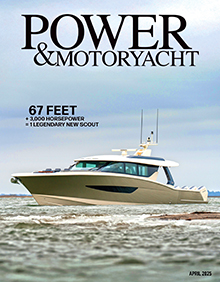

Fueled up and ready to boogie, our Bertram 35 test boat awaits, twiddling her thumbs in the haulout slip at Bertram’s relatively new facility in Tampa, Florida. Does she look like the old Bertram 31, her Spartan but storied predecessor? Absolutely, although she’s totally modern in terms of fit, finish, and outfitting.

Bertram 35

The machinery space of our Bertram 35 would have been a bit roomier if her owner had foregone the optional SeaKeeper 5 (between the mains, just abaft the Fisher-Panda genset), but then again there’s that flip-the-switch-for-sidewalk-type-stability thing he may have been thinking of. When deployed, the SeaKeeper on our test boat reduced roll in 4-foot swells to just about zilch! The boat went up and down, but side to side? Nope!

Bertram 35

Absolute simplicity! As you can see, the Palm Beach-style helm station on our Bertram 35 test boat (with optional varnished high-gloss helm pod) has been stripped of all peripherals. There’s little more than a couple of Garmin MFDs, a command mic, a compass, and a Caterpillar engine readout. The small panel just to the right of the engine-control lever to starboard (with rubber bow thruster button) governs the operation of the SeaKeeper gyro stabilizer.

Bertram 35

The engineering guy for the Bertram 35 project, Earl Blackwell, shows us the mockup for the next Bertram model to go into production—the Bertram 60. While the hull of the 35 is infused (achieving a 70-to-30 percent glass-to-resin ratio, according to Bertram), resin-infusion technology will be used to create both the hull and the deck of the 60.

Bertram 35

Bertram engineer Earl Blackwell points out the seamlessness of the Bertram 35’s flybridge molding prior to its installation. While the part appears to be a single, unified structure, it is actually composed of five separate, highly-durable parts, bolted and fiberglassed together.

Bertram 35

Read our boat test of the Bertram 35 here. ▶

VIDEO: Learn about the Vetus Bow Thruster on the Bertram 35 here. ▶