Save Money Quietly

Properly maintained motor mounts result in more than just a vibration-free ride.

Regardless of what fuel prices are doing (wise not to think about it too much), it’s best to get as much as you can from every tank of fuel. Smart boaters are looking closely at their engines and tuning them for maximum efficiency. But based on my experience, it’s a safe bet that even many experienced boaters are overlooking one critical area.

“People really don’t start thinking about their engine mounts until they have an issue,” said Ken Maust, vice president at Bushings Inc., in Rochester Hills, Michigan, where the company has been making vibration-dampening engine mounts for marine applications for more than 50 years.

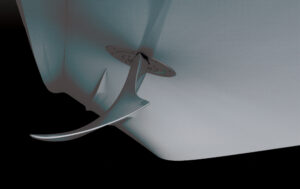

When you’re looking at replacing motor mounts, you’re doing so primarily because you want to eliminate or at least significantly reduce a noticeable vibration or noise from the engines, generators, air-conditioning compressors, and even freshwater-system pumps. But mounts also help maintain alignment between the engines and shafts in inboard or stern-drive installations. When components are properly aligned, the whole system runs more efficiently, improving fuel economy.

So, aside from having a mount fail, which causes a serious misalignment and the resultant obvious vibration, what should you look for to determine if your boat’s mounts need replacing? And what are your considerations for new ones?

Some mounts need to be replaced after ten years, while others will last for three decades. As with so many other aspects of boat maintenance, it depends on variables such as how often you use the boat, the conditions in which you operate, and how hard you run when the waves get big.

To check the health of your mounts, the best thing to do is visually inspect them. If the engine’s bracket is sitting all the way down on the mount’s stud, the elastomer (the rubber element inside the mount) has lost its elasticity. This reduces the mount’s ability to absorb vibration and it should be replaced. Conversely, if your mounts are sitting fairly high on the stud, you’re good to go.

When selecting new mounts, match the size of the mounting hole in the casting to the bolts that are driven into the bearer/stringer. You must also determine the correct stud size for your engines’ brackets. If one mount needs replacing, you should do all four. You want consistent elasticity in the elastomer. Finally, choose a material that will last in the environment in which you boat. Some mount bases are stamped steel. Others are cast aluminum, which will last longer in salt water.

Mounts are rated based on the weight of the engine and the power output. If you’re repowering, the engine manufacturer will provide a mount with the motor. Among the best-known makers of mounts are Bushings Inc., Trelleborg (sold in the United States by Mission Sales & Supply in Mansfield, Texas), and Barry Controls. Prices vary, but you can usually get a quality mount with a fluid- and heat-resistant elastomeric polymer for anywhere from $50 to $100 per mount for an average-size diesel engine.

You’ll also have a choice of mount styles. Trelleborg’s Cushyfloat has a protective cap over the polymer with the stud coming up through the cap. Bushings Inc. and Barry Controls have a more open design with the stud exposed and the elastomer housed in the base.

Maust did say that no matter which mount you choose, make sure it has a fail-safe design. If the boat rolls over or collides with a seawall, the mount needs to ensure that the engine stays in position. For example, the Bushings products have a bumper stop on the bottom to keep the elastomer from dropping too far and a lip on the base to ensure that the elastomer can’t pop out.

And when the elastomer and mount stay in place, they’re like having good insurance. You’re glad you have it, but you never even think about it.

This article originally appeared in the June 2012 issue of Power & Motoryacht magazine.