Outboards with issues can be costly to repair, so hire an engine surveyor before you buy a used boat.

Last time I looked, neither Yamaha nor Honda nor Mercury nor Suzuki nor any other builder of outboard motors was giving away engines. And qualified mechanics weren’t performing repairs for chump change either, so a serious engine problem could cost you a considerable pile of greenbacks. If you already own an outboard boat with propulsion issues, good luck—but maybe repair isn’t the answer: It could be time to sell your lame duck and move into another boat that’s bigger, newer, faster or more efficient. Let someone else worry about those old motors. Just beware of the guy who’s doing the same thing: dumping a vessel with bum outboards on an unsuspecting sap. Don’t be that sap. Before handing over a Halliburton full of Franklins or a cashier’s check with the numbers running off the edge, call an engine surveyor.

We all know that it’s important to have any boat surveyed before sealing the final deal, but most yacht surveyors aren’t engine surveyors. Sure, they might pop the cowling and look things over, check for oil leaks, cracked spark plug leads, excessive corrosion and other problems in plain sight. But they typically don’t take anything apart, other than open the oil drain on the lower unit and see what drips out. I’m told that in the “old days,” whenever that was, surveyors would do compression checks on a motor or motors as part of the survey. I don’t see that today, although some surveyors offer such checks for an extra fee.

A compression test, by the way, measures how much each piston is compressing the air in the cylinder, using a simple gauge threaded into the spark plug port. Compression-testing a cold engine won’t give accurate results, so the engine has to be warmed up to operating temperature before pulling the plugs. Comparing the test results with the factory specs for the engine as new suggests the general state of the cylinders, pistons and piston rings; as the engine wears, the compression gradually decreases. Depending on which expert you ask, the ideal is for all the cylinders to read within 10 or maybe even 15 percent of each other. Greater variation in one or more readings indicates problems specific to a particular cylinder or set of cylinders, maybe a broken piston ring, or bad valves, a blown gasket, etc. If there’s a problem, an engine surveyor can run further tests using equipment and knowledge a typical yacht surveyor won’t have.

But don’t go running out to buy a compression test kit quite yet—there’s more to an outboard motor than compression, and there’s an easier way to diagnose the overall condition of a motor now that we’re in the 21st century. Most outboard motors (and inboards and diesels, too) are electronic, and have been since the 1990s: electronic fuel injection, electronic ignition, electronics all over the place, with sensors that feed information on the state of each system to anyone with the ability to access it. And that “anyone” is typically a mechanic or engine surveyor with a laptop and the appropriate diagnostic software—maybe someone like Capt. John Banister of Palm Beach Gardens, Florida, or Robert T. Scanlan from Nahant, Massachusetts, two engine surveyors with years of experience and a boatload of certifications and training. Both men are also qualified marine surveyors and can do an overall survey of a vessel and her engines.

When I asked Banister and Scanlan what they look for when surveying an outboard, both said the most important thing is to see detailed maintenance records: What was done, when it was done and who did it. Without records to prove the engine has been properly maintained, the safest bet is to assume it hasn’t. Here’s where electronic diagnostics come into play. Outboard dealers and their mechanics have proprietary software for analyzing engines, tech that’s not available to independent mechanics.

There are, however, other programs anybody can buy. One is the Marine Engine Diagnostic System (M.E.D.S.) from CDI Electronics in Huntsville, Alabama. A technician I spoke with at CDI said that M.E.D.S. was designed specifically for the mechanic who doesn’t have access to a dealer’s software. M.E.D.S. supports almost every outboard and gasoline inboard engine manufactured since 2000, and some that are even older; more models are being added continuously, said the tech. (There are similar programs that can diagnose both gas and diesel engines; Jaltest is one, TEXA another.)

According to Banister, the only thing M.E.D.S. won’t let him do is change the engine’s factory-set parameters—the timing, for example. But it will do all the diagnostics he needs for an engine survey. (Note that Banister is also a factory-certified mechanic for most brands of outboards, so his surveys go deeper than just diagnostics.) Scanlan said that hooking up a laptop to an engine—every manufacturer uses a different connector, so Scanlan carries one laptop and a pile of cords—is like accessing a person’s medical records. “Maybe you broke your leg playing street hockey when you were a teenager. It healed up, but it’s still in your records. Same with an engine,” he said. “The diagnostics shows what happened and when it happened, during what hour of operation, down to the tenth of an hour.”

I tagged along with Scanlan on his survey of a center console with twin 300-hp Suzuki outboards. Once his laptop was plugged into the data port on an engine, M.E.D.S. first scanned for active fault codes; serious faults display in red, others in orange. “I look for fault codes even before I do the sea trial,” he said. “I don’t start the engine, but just switch on the ignition. Any fault codes and I stop the survey. They have to be repaired.” With the engines running, Scanlan’s computer pulled up a complete dossier on each motor: How many total hours of operation (681.2 for one engine, 681.5 for the other); how many hours at various RPM settings—these motors had about 20 percent wide-open-throttle operation, which was fine with Scanlan; when the oil was last changed (42.5 hours of running time ago, for both engines); were there any past faults, like overheating, low oil pressure or various sensor failures—there were none. If there had been, the program would have provided more information.

Scanlan then ran the cylinder drop test, sort of a virtual compression test: M.E.D.S. shuts down one cylinder at a time. With electronic ignition and fuel injection, software can do that, and it records the drop in RPM, displaying the results graphically. All cylinders should have the same effect when dropped; if one has less effect when cut off, there’s a problem with that cylinder, and further investigation is necessary. The surveyor doesn’t fix the problems but should be able to advise the interested parties on how to proceed. (Surveys, after all, are performed to locate and evaluate deficiencies in a vessel that could affect the purchase price, or kill the deal completely.)

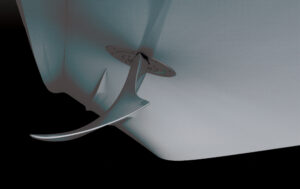

In our case, everything was copacetic. After the boat was hauled, Scanlan checked the lower-unit oil for water or signs of overheating—the oil would smell burned and/or appear milky—and looked for metal filings on the magnetic drain plug, which indicate gear wear. Again, nothing. He checked the stainless-steel props for damage and looked for reconditioning numbers on the hubs. “If the props have been reconditioned, maybe they hit something; in that case, you need to check the shaft, too,” Scanlan said. He inspected the tilt/trim cylinders for leaking oil and looked for corrosion in the nooks and crannies of the engine mount, where many folks don’t rinse off the salt thoroughly after a run. No problems here, either. Finally, he pumped environmentally friendly antifreeze from a tank in his van through the outboards to winterize them, as a courtesy. “I buy it by the 55-gallon drum,” he said. Scanlan would later print out the M.E.D.S. results and send them to his client, along with his recommendations.

John Banister, on the other hand, doesn’t worry about winterizing—he covers Florida from Daytona to the Keys from his shop in Palm Beach Gardens. Banister is a factory-certified technician for most outboards and some gasoline inboards; he doesn’t survey or work on gas engines, for which he is not certified, nor on diesels. His engine surveys go very deep into the motor; as a mechanic, he’s not afraid of taking things apart when necessary. But before hiring a surveyor, he said, go online and look for recalls for the engine, or service bulletins. Study the service invoices; maintenance and repairs should be done by reputable shops, following the factory schedule. Has the lower unit been checked? When was the water pump serviced? What about timing belt replacements? “Before you put any money in escrow, get a sea trial,” he said. “Run the boat at full throttle to make sure it can go to max rated RPM.” When the engine’s warm, you shouldn’t smell any gas, he added.

Two common problems Banister sees are corrosion from non-use of the engine (I thought folks in Florida went boating all the time!), and phase separation of gasoline that’s been left in the tank for too long. Corrosion can be more damaging than not servicing the engine. “I’d rather see an engine with higher hours than one that’s not been used,” he said. Phase separation lowers the octane of the gas, which in turn causes the fuel to detonate rather than burn evenly. This can damage the engine. The best cure for phase-separated gas is to empty the tank and refill it with fresh, ideally non-ethanol, fuel. During every survey, Banister takes a sample of gasoline from the motor’s injector rail and checks the quality.

His surveys also include computer diagnostics, using one of two programs he owns; thermal imaging of the engine under load to look for overheating (the thermostat’s at the top of the powerhead, so overheating usually starts at the bottom); an inductive ignition test—a magnetic sensor touched to the ignition coils shows the voltage for each one; and a conventional compression test. If a cylinder shows low compression, he’ll squirt a little oil in and do the test again. If the compression increases, it’s probably a piston-ring problem. (This will show up as excess chromium on the oil analysis, which Banister also does for each engine.) Otherwise, he performs a leak-down test: After manually cranking the engine to bring a given cylinder to top dead center, when both intake and exhaust valves are closed, Banister then pumps in about 90 psi of compressed air. A gauge shows how long the cylinder holds the pressure. As the pressure falls, Banister listens for escaping air. If it comes out through the hub exhaust, there’s an exhaust valve problem; through the air intake, it’s an intake valve; through the dipstick tube, probably a damaged piston ring that’s letting air into the crankcase. Valve problems are mostly caused by internal corrosion, he said. A corroded valve doesn’t seat properly, which causes it to overheat—the valve’s cooled by resting against the motor’s water-cooled head. A hot valve can act like a spark plug, detonating the gas as soon as it’s injected rather than when it should be firing off.

A reputable engine surveyor should be an experienced mechanic certified for the engine under consideration, Banister advised. He or she will know what’s going on inside the engine and be able to make an informed analysis of whatever issues show up during the survey—and there are frequently more than one. And not everything that can cost you money has a sensor, so diagnostic testing alone isn’t enough. This is where experience comes in: “There’s no substitute for cranking on wrenches,” Banister said. Expect the engine survey to take at least half a day for twins, a full day for triples and quads, and to cost—well, more than you might think if you hire a qualified person. For example, Banister charges $650 to survey a pair of Yamaha inline fours, including fluid analysis, and prices go up from there. But he often finds problems that a more general survey wouldn’t reveal, issues that can cost thousands of dollars to repair. So, I repeat: Don’t be a sap when you buy your next outboard. Get out your checkbook and hire a top-notch engine surveyor to ensure the motors you’re buying are up to snuff. It could be money well spent.